Automated Warehouse Technical Applications

In automated warehouses, equipment requires high-speed transport, heavy load operation, precise positioning, and low vibration. HICKWALL’s Mecanum wheels, AGV/AMR wheels, OHT wheels, industrial casters, leveling mounts, and aluminum extrusion accessories are widely used in AGV transporters, intelligent storage racks, sorting systems, and overhead conveyor systems, providing efficient, safe, and stable logistics solutions.

Technical Product Highlights

1. Mecanum Wheels

Omnidirectional movement: supports X/Y axes and rotation for flexible transport

Load capacity: 50~1500 kg/wheel

Low friction PU surface for higher efficiency

Low vibration design minimizes load swaying

Wear-resistant & ESD-safe for extended service life

2. AGV/AMR Wheels

Heavy load capacity: 200~1000 kg/wheel

Low rolling resistance & precision bearings improve battery efficiency

Wheel material: PU or TPU, wear-resistant & chemical-resistant

Dustproof & ESD-safe for sensitive electronics

3. OHT Wheels

Designed for overhead transport & suspension conveyors

High wear & corrosion-resistant materials for continuous operation

Precision concentricity ±0.05 mm for stable load transport

Low-noise bearings reduce warehouse noise

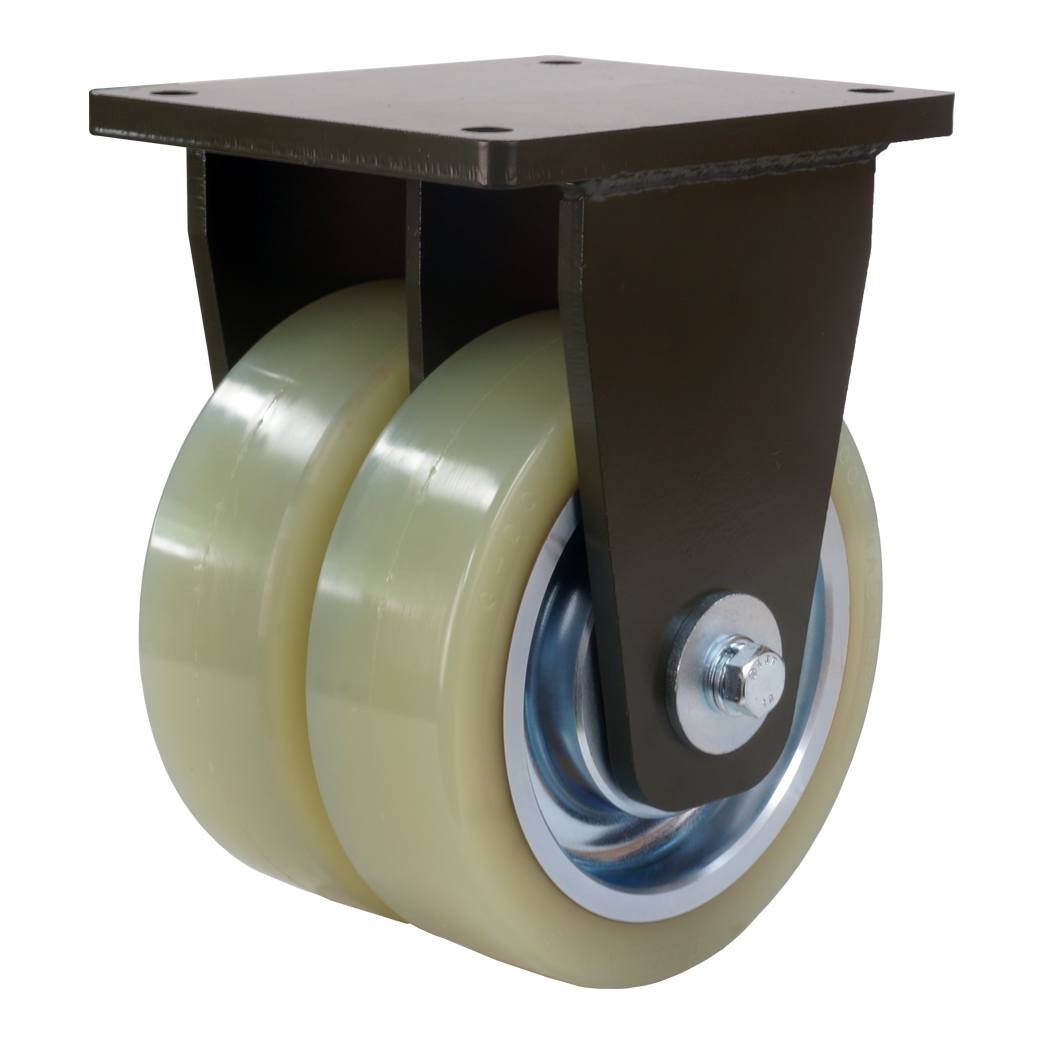

4. Industrial Casters

Heavy-duty load: 50~8000 kg/caster

Dual brake system ensures stable positioning

Anti-vibration design minimizes impact on warehouse systems

Wear & chemical-resistant materials

5. Leveling Mounts

Micro-adjustment precision ±0.2 mm ensures racks & equipment remain level

Vibration damping reduces transmission

Customizable threads, baseplates, and materials for different warehouse setups

6. Aluminum Extrusion Accessories

Modular design for rapid assembly of racks & automated systems

Aluminum 6063-T5, high strength & corrosion-resistant

T-slot profiles support multiple mounting options

Lightweight yet strong, load capacity 50~300 kg/m

Technical Product Highlights

1. Mecanum Wheels

Omnidirectional movement: supports X/Y axes and rotation for flexible transport

Load capacity: 50~1500 kg/wheel

Low friction PU surface for higher efficiency

Low vibration design minimizes load swaying

Wear-resistant & ESD-safe for extended service life

2. AGV/AMR Wheels

Heavy load capacity: 200~1000 kg/wheel

Low rolling resistance & precision bearings improve battery efficiency

Wheel material: PU or TPU, wear-resistant & chemical-resistant

Dustproof & ESD-safe for sensitive electronics

3. OHT Wheels

Designed for overhead transport & suspension conveyors

High wear & corrosion-resistant materials for continuous operation

Precision concentricity ±0.05 mm for stable load transport

Low-noise bearings reduce warehouse noise

4. Industrial Casters

Heavy-duty load: 50~8000 kg/caster

Dual brake system ensures stable positioning

Anti-vibration design minimizes impact on warehouse systems

Wear & chemical-resistant materials

5. Leveling Mounts

Micro-adjustment precision ±0.2 mm ensures racks & equipment remain level

Vibration damping reduces transmission

Customizable threads, baseplates, and materials for different warehouse setups

6. Aluminum Extrusion Accessories

Modular design for rapid assembly of racks & automated systems

Aluminum 6063-T5, high strength & corrosion-resistant

T-slot profiles support multiple mounting options

Lightweight yet strong, load capacity 50~300 kg/m

Related Products