Automobile Factory

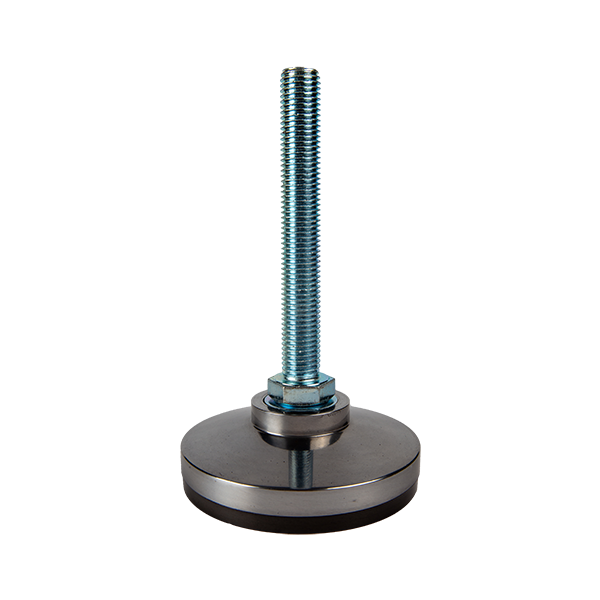

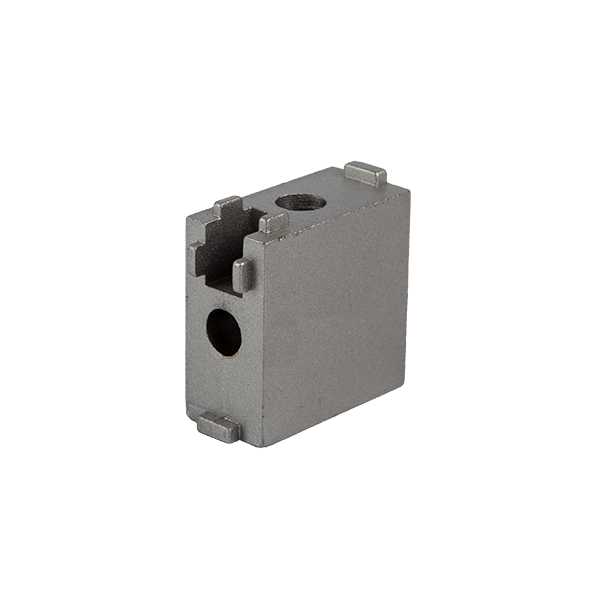

Regarding the application of automobile factories, Hickwall has quite rich experience in the use of industrial wheels. Whether it is a traditional automobile factory or an advanced automated automobile factory production line, it can use shock-absorbing wheel series, ultra-high load wheel series and AGV special wheel series to perfectly achieve the smooth operation of the production line of the automobile factory.

Related Products