Aerospace Industry Applications

In the aerospace industry, Mecanum wheels, AGV/AMR specialized wheels, OHT wheels, industrial casters, leveling mounts, and aluminum extrusion accessories are widely applied in:

Aircraft assembly and maintenance platforms: Providing stable support and precise adjustments to ensure high-precision assembly and maintenance processes.

Airport logistics and handling systems: Supporting efficient transportation of aircraft components, tools, and equipment.

Automated production lines and testing equipment: Enhancing production efficiency and testing accuracy to ensure product quality.

Airport ground service equipment: Such as boarding bridges and baggage carts, ensuring smooth and safe ground operations.

Technical Applications

1. Mecanum Wheels

Omnidirectional movement capability: Achieving precise positioning in confined spaces without the need for turning, suitable for aircraft component handling.

Low noise design: Reducing noise pollution in the working environment, meeting airport operation requirements.

Electrostatic discharge (ESD) protection: Preventing static accumulation to protect sensitive electronic equipment.

2. AGV/AMR Wheels and Casters

High load capacity: Supporting the automated transport of heavy aircraft components.

Durable and wear-resistant: Adapting to long operating hours, reducing maintenance costs.

ESD design: Preventing static damage to electronic devices.

3. OHT Wheels

Precise positioning function: Ensuring accurate placement of aircraft components in automated transport systems.

High stability: Adapting to high-speed operations, ensuring efficient production line functioning.

4. Industrial Casters

High load design: Supporting the movement and positioning of large equipment.

Shock absorption and anti-slip features: Ensuring equipment stability during operation.

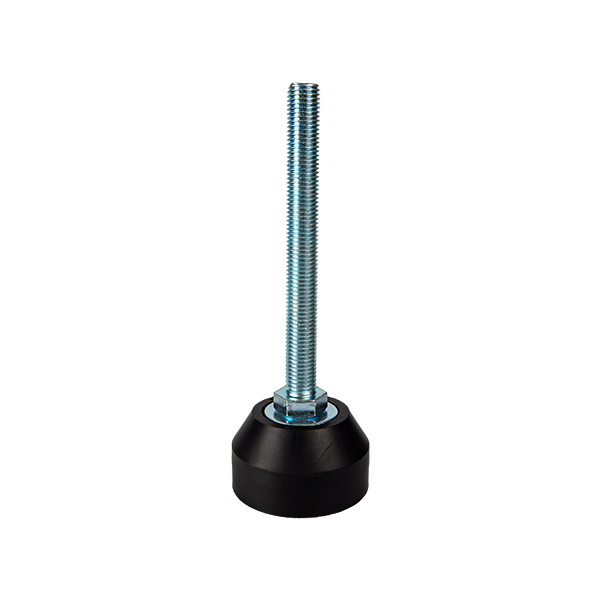

5. Leveling Mounts

Precise adjustment function: Ensuring horizontal stability of equipment during assembly and maintenance processes.

Vibration damping design: Protecting equipment from external vibrations.

6. Aluminum Extrusion Accessories

Modular design: Rapidly constructing various equipment supports and work platforms.

High strength and lightweight: Meeting the dual requirements of structural strength and weight in the aerospace industry.

Applications by Domestic and International Airlines

Boeing: Utilizing Mecanum wheels and AGV systems in aircraft assembly lines for automated component handling, enhancing production efficiency.

EVA Air: Applying industrial casters and leveling mounts in airport ground services to ensure equipment stability and flexibility.

China Airlines: Using aluminum extrusion accessories and OHT systems in maintenance platforms for efficient and precise maintenance processes.

Aircraft assembly and maintenance platforms: Providing stable support and precise adjustments to ensure high-precision assembly and maintenance processes.

Airport logistics and handling systems: Supporting efficient transportation of aircraft components, tools, and equipment.

Automated production lines and testing equipment: Enhancing production efficiency and testing accuracy to ensure product quality.

Airport ground service equipment: Such as boarding bridges and baggage carts, ensuring smooth and safe ground operations.

Technical Applications

1. Mecanum Wheels

Omnidirectional movement capability: Achieving precise positioning in confined spaces without the need for turning, suitable for aircraft component handling.

Low noise design: Reducing noise pollution in the working environment, meeting airport operation requirements.

Electrostatic discharge (ESD) protection: Preventing static accumulation to protect sensitive electronic equipment.

2. AGV/AMR Wheels and Casters

High load capacity: Supporting the automated transport of heavy aircraft components.

Durable and wear-resistant: Adapting to long operating hours, reducing maintenance costs.

ESD design: Preventing static damage to electronic devices.

3. OHT Wheels

Precise positioning function: Ensuring accurate placement of aircraft components in automated transport systems.

High stability: Adapting to high-speed operations, ensuring efficient production line functioning.

4. Industrial Casters

High load design: Supporting the movement and positioning of large equipment.

Shock absorption and anti-slip features: Ensuring equipment stability during operation.

5. Leveling Mounts

Precise adjustment function: Ensuring horizontal stability of equipment during assembly and maintenance processes.

Vibration damping design: Protecting equipment from external vibrations.

6. Aluminum Extrusion Accessories

Modular design: Rapidly constructing various equipment supports and work platforms.

High strength and lightweight: Meeting the dual requirements of structural strength and weight in the aerospace industry.

Applications by Domestic and International Airlines

Boeing: Utilizing Mecanum wheels and AGV systems in aircraft assembly lines for automated component handling, enhancing production efficiency.

EVA Air: Applying industrial casters and leveling mounts in airport ground services to ensure equipment stability and flexibility.

China Airlines: Using aluminum extrusion accessories and OHT systems in maintenance platforms for efficient and precise maintenance processes.

Related Products