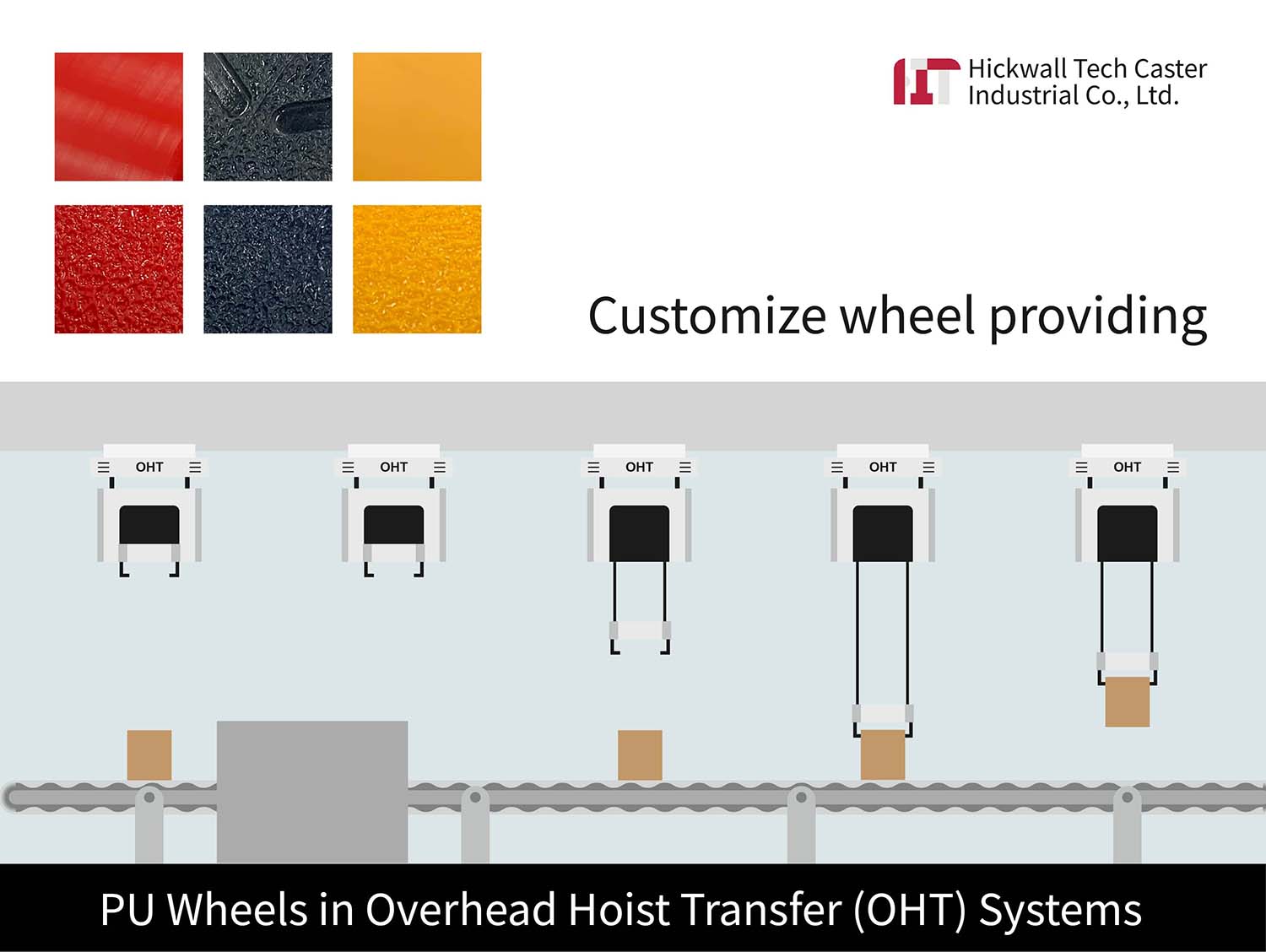

Elevating Efficiency: PU Wheels in Overhead Hoist Transfer (OHT) Systems

In the dynamic realm of material handling, precision and efficiency are paramount. Industries rely on advanced technologies to streamline processes, and Overhead Hoist Transfer (OHT) systems stand out as versatile solutions. At the heart of the seamless movement in these systems lie the wheels, and when it comes to ensuring optimal performance, Polyurethane (PU) wheels emerge as a game-changer. In this article, we explore the crucial role of PU wheels in OHT systems and how they contribute to enhanced efficiency in material handling applications.

Understanding Overhead Hoist Transfer (OHT) Systems

Before delving into the benefits of PU wheels, it's crucial to understand the significance of OHT systems. OHT systems are a type of automated guided vehicle (AGV) system designed for the efficient movement of materials within a facility. These systems utilize a combination of overhead tracks and hoists to transport materials, providing a flexible and space-efficient solution for industries ranging from manufacturing to warehousing.

The Importance of Wheel Selection in OHT Systems

In an OHT system, the wheels are the literal and metaphorical foundation of smooth material movement. The right choice of wheels is critical for several reasons:

- Precision Movement: OHT systems often operate in confined spaces and require precise movement to navigate through intricate paths and deliver materials accurately. The choice of wheels significantly influences the agility and accuracy of the system.

- Load Capacity: OHT systems are tasked with transporting various loads, from lightweight materials to heavy components. The wheels must be capable of bearing these loads without compromising performance or safety.

- Durability: Continuous operation and the nature of material handling environments expose wheels to wear and tear. Durable wheels are essential to minimize maintenance and replacement frequency, ensuring uninterrupted system operation.

Polyurethane (PU) Wheels: The Ideal Choice for OHT Systems

Polyurethane (PU) wheels emerge as the ideal solution to address the specific demands of OHT systems. Here's why:

- Exceptional Load-Bearing Capacity: PU wheels are known for their high load-bearing capacity. In OHT systems where various loads are transported, PU wheels provide the strength needed to support heavy materials, ensuring stability and reliability in operations.

- Precise Maneuverability: PU wheels offer a perfect blend of hardness and resilience, providing excellent traction and grip. This is crucial for OHT systems, especially in scenarios where precise maneuverability is essential for navigating through intricate paths and delivering materials accurately.

- Reduced Noise Levels: Noise reduction is a key consideration in many industrial settings. PU wheels are renowned for their quiet operation, contributing to a quieter and more conducive working environment, particularly in applications where OHT systems operate in close proximity to workers.

- Resistance to Wear and Tear: PU wheels exhibit remarkable resistance to abrasion and wear. In the demanding environment of material handling, where wheels are subjected to continuous movement and varying floor conditions, the durability of PU wheels ensures a longer service life, reducing downtime and maintenance costs.

- Chemical Resistance: OHT systems may encounter a variety of substances in industrial environments. PU wheels offer resistance to many chemicals, adding another layer of reliability in diverse working conditions.

HICKWALL TECH's PU Wheels: Elevating OHT System Performance

HICKWALL TECH CASTER INDUSTRIAL CO., LTD. takes pride in offering PU wheels that are specifically engineered to meet the unique requirements of OHT systems. With a meticulous focus on load capacity, precision, and durability, our PU wheels elevate the performance of OHT systems in diverse industrial applications. The versatility of our PU wheels ensures that they seamlessly integrate into various material handling scenarios, contributing to the overall efficiency of OHT systems.

Conclusion: Optimizing OHT Systems with PU Wheels

In the ever-evolving landscape of material handling, the efficiency and precision of systems like Overhead Hoist Transfer (OHT) are pivotal for success. PU wheels, with their exceptional load-bearing capacity, precise maneuverability, reduced noise levels, and resistance to wear and tear, emerge as a cornerstone in enhancing the performance of OHT systems. HICKWALL TECH's commitment to excellence is evident in its range of PU wheels designed to meet the dynamic needs of modern industrial environments. As industries continue to embrace advanced material handling solutions, PU wheels stand as a testament to innovation and reliability, ensuring that OHT systems operate at their optimal best, day in and day out.

Don't hesitate to contact us for:

- Expert Guidance: Our team is here to answer your questions and provide expert advice on selecting the most suitable wheels for your application.

- Custom Solutions: If your application demands a tailored approach, we specialize in creating custom wheel solutions that precisely meet your unique requirements.

- Product Information: Whether you need more details about a specific product or want to explore our entire range, we are here to provide comprehensive information.

- Quotes and Orders: For pricing inquiries or placing orders, our customer service team is dedicated to facilitating a seamless process.