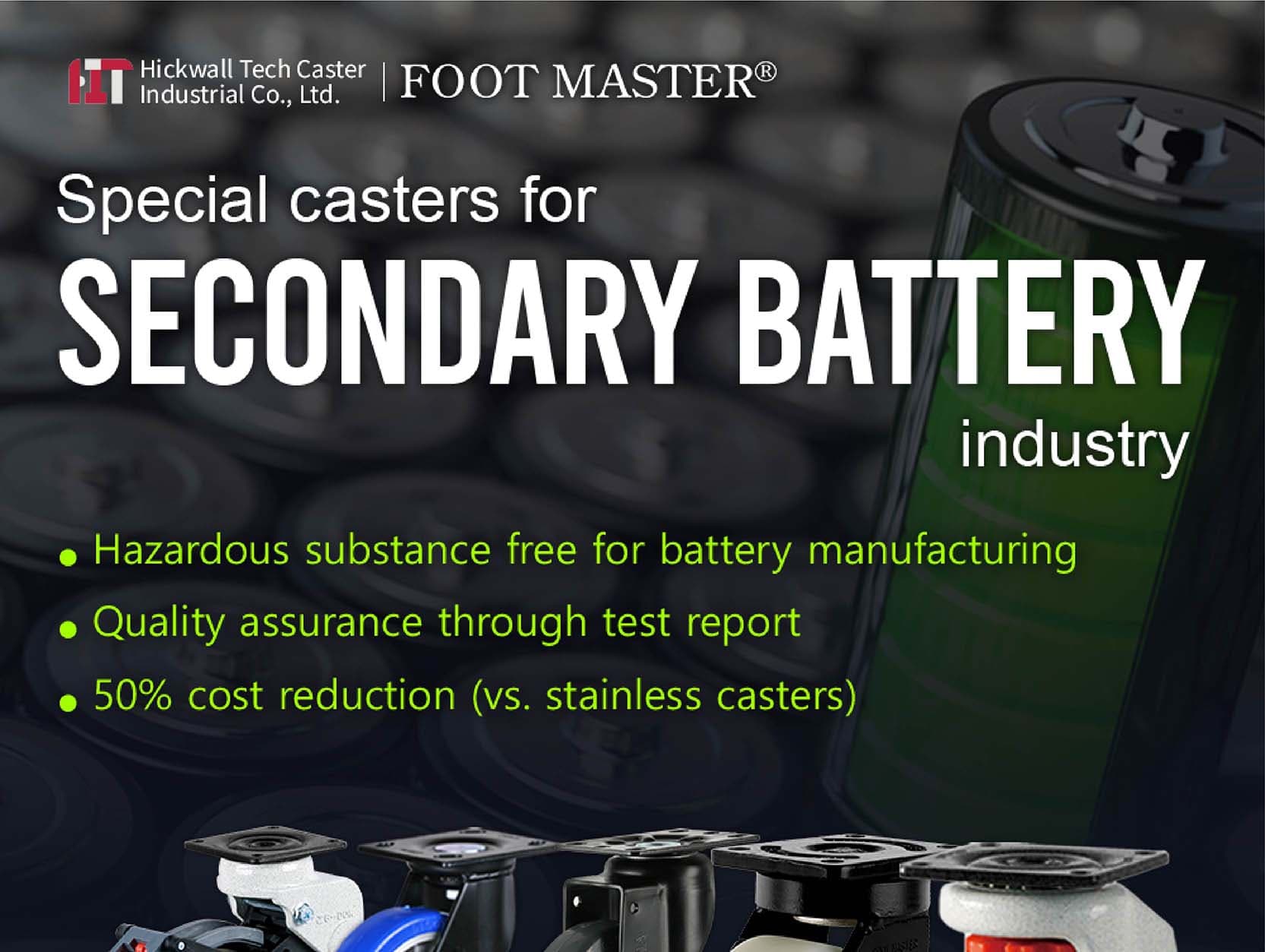

Special Caster for Secondary Battery and Energy Industry

What are caster wheels specifically for secondary batteries?

In the rapidly evolving secondary battery and energy industry, ensuring the safety and efficiency of manufacturing processes is paramount. Caster wheels for secondary batteries are critical components designed to meet the specific needs of battery manufacturing environments. These specialized casters are developed to eliminate hazardous regulated substances traditionally used in manufacturing, reducing risks and enhancing operational safety.

Why Choose Specialized Casters?

Material Selection and Design: For the battery industry, it's essential to use materials that minimize the risk of contamination and enhance durability. Stainless steel caster frames or nickel-plated caster frames are recommended due to their resistance to corrosion and their ability to withstand harsh environments. Despite their higher cost and limited availability in the market, these materials provide unmatched performance and quality, crucial for the sensitive nature of battery manufacturing.

The Difference Between Secondary Battery Casters and Standard Casters

Standard commercially available caster wheels often contain substances that pose a risk of sparking or reacting, potentially leading to battery explosions. In contrast, Hickwall’s casters for the battery and energy industry are designed to mitigate these risks by using materials like stainless steel and electroless nickel, which are safer and more reliable but come at a premium price.

Introducing HICKWALL's Exclusive Battery Casters

Recognizing the need for specialized solutions, HICKWALL has launched the world's first caster series exclusively designed for the secondary battery and energy industry. Our innovative battery caster lineup includes:

- LEVELING CASTR - GDN Series: Models GDN-40, GDN-60, GDN-80, GDN-150

- SHOCK ABSORBING CASTER - GDS Series: Models GDS-100, GDS-125, GDS-130, GDS-150, GDS-200

- HEAVY DUTY CASTER - GXT Series: Models GXT-80, GXT-100, GXT-125, GXT-150, GXT-200

These casters are specifically designed for high-load applications and dynamic environments typical in battery production lines.

Advantages of Using HICKWALL Casters

- Enhanced Safety: Our casters are engineered to be free from hazardous substances, reducing the risk of accidents during the battery manufacturing process.

- Quality and Compliance: Each caster is accompanied by a detailed report guaranteeing compliance with industry standards and safety regulations.

- Cost-Effective: Our casters offer a significant cost reduction—up to 50% compared to traditional stainless steel casters—without compromising quality or performance.

Conclusion

For battery and energy storage equipment production lines still using low-quality stainless steel casters, HICKWALL offers a superior alternative. Our industrial secondary battery casters are not just cost-effective but are specifically designed to meet the unique needs of the battery and energy industry. With Hickwall, upgrade your production line with casters that guarantee higher performance, safety, and quality.

If you're ready to enhance the efficiency and safety of your operations, don't hesitate to reach out.